What are the important product categories of shunt capacitors?

Important Product Categories of Shunt Capacitors

I. Introduction

Shunt capacitors are essential components in electrical systems, playing a crucial role in enhancing the performance and efficiency of power distribution networks. By providing reactive power support, shunt capacitors help to stabilize voltage levels, improve power factor, and reduce energy losses. This blog post aims to explore the important product categories of shunt capacitors, including their types, materials, voltage ratings, applications, and selection criteria, ultimately highlighting their significance in modern electrical systems.

II. Types of Shunt Capacitors

A. Fixed Shunt Capacitors

Fixed shunt capacitors are designed to provide a constant capacitance value, making them suitable for applications where the reactive power requirement does not change significantly. These capacitors are commonly used in power factor correction, voltage stabilization, and energy storage.

**Advantages:**

- Simplicity in design and installation.

- Cost-effective for applications with stable load conditions.

**Disadvantages:**

- Limited flexibility; cannot adjust to varying load conditions.

- Potential for overvoltage issues if not properly sized.

B. Variable Shunt Capacitors

Variable shunt capacitors allow for adjustable capacitance values, making them ideal for applications where reactive power needs fluctuate. These capacitors can be manually or automatically adjusted to match the system's requirements.

**Advantages:**

- Flexibility to adapt to changing load conditions.

- Improved efficiency in power factor correction.

**Disadvantages:**

- More complex design and installation compared to fixed capacitors.

- Higher initial costs due to the adjustable mechanism.

C. Automatic Shunt Capacitors

Automatic shunt capacitors are equipped with control systems that automatically adjust the capacitance based on real-time load conditions. These capacitors are particularly useful in dynamic environments where load variations are frequent.

**Advantages:**

- Optimal performance with minimal human intervention.

- Enhanced reliability in maintaining power factor and voltage levels.

**Disadvantages:**

- Higher complexity and cost due to the control systems.

- Maintenance requirements for the control mechanisms.

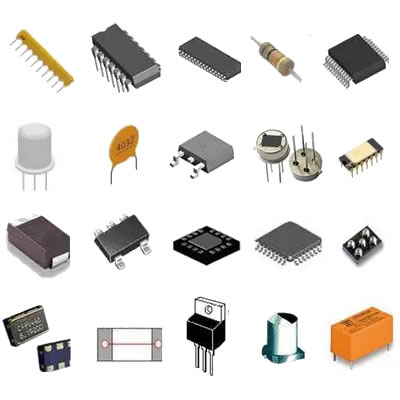

III. Material Categories of Shunt Capacitors

A. Ceramic Shunt Capacitors

Ceramic shunt capacitors are made from ceramic materials, offering excellent stability and reliability. They are commonly used in high-frequency applications and environments with high temperatures.

**Benefits:**

- High dielectric strength and stability.

- Suitable for high-frequency applications.

**Limitations:**

- Limited capacitance values compared to other materials.

- More susceptible to mechanical stress.

B. Film Shunt Capacitors

Film shunt capacitors utilize thin plastic films as the dielectric material. They are known for their low losses and high insulation resistance, making them suitable for various applications, including power factor correction and energy storage.

**Benefits:**

- Excellent thermal stability and low self-heating.

- High reliability and long lifespan.

**Limitations:**

- Larger physical size compared to ceramic capacitors.

- Limited voltage ratings in some cases.

C. Electrolytic Shunt Capacitors

Electrolytic shunt capacitors are polarized capacitors that offer high capacitance values in a compact size. They are commonly used in applications requiring significant reactive power support.

**Benefits:**

- High capacitance values in a small footprint.

- Cost-effective for large-scale applications.

**Limitations:**

- Limited lifespan and reliability compared to other types.

- Polarized nature restricts their application in AC circuits.

IV. Voltage Ratings of Shunt Capacitors

A. Low Voltage Shunt Capacitors

Low voltage shunt capacitors are designed for applications operating at voltages up to 1 kV. They are commonly used in residential and commercial power systems for power factor correction and voltage stabilization.

**Key Features:**

- Compact size and lightweight.

- Cost-effective for low voltage applications.

B. Medium Voltage Shunt Capacitors

Medium voltage shunt capacitors operate in the range of 1 kV to 35 kV. They are typically used in industrial applications and substations to improve power quality and reduce losses.

**Key Features:**

- Robust design to withstand higher voltage levels.

- Enhanced performance in industrial environments.

C. High Voltage Shunt Capacitors

High voltage shunt capacitors are designed for applications exceeding 35 kV. They are essential in transmission and distribution networks, providing reactive power support and voltage regulation.

**Key Features:**

- Designed for high reliability and performance.

- Capable of handling significant reactive power demands.

V. Applications of Shunt Capacitors

A. Power Factor Correction

Power factor correction is one of the primary applications of shunt capacitors. By providing reactive power, shunt capacitors help to improve the power factor of electrical systems, reducing energy losses and improving overall efficiency.

**Importance:**

- Enhances the efficiency of power systems.

- Reduces demand charges from utility companies.

B. Voltage Stabilization

Shunt capacitors play a vital role in maintaining stable voltage levels in electrical systems. By compensating for reactive power demands, they help to prevent voltage fluctuations that can lead to equipment damage and operational inefficiencies.

**Benefits:**

- Improved reliability of electrical equipment.

- Enhanced performance in industrial and commercial applications.

C. Harmonic Filtering

Harmonics are unwanted frequencies in electrical systems that can cause distortion and inefficiencies. Shunt capacitors can help mitigate harmonic distortion by providing a path for harmonic currents, improving the overall power quality.

**Explanation:**

- Shunt capacitors absorb and filter out harmonic currents.

- They contribute to a cleaner and more efficient electrical system.

VI. Selection Criteria for Shunt Capacitors

A. Application Requirements

When selecting shunt capacitors, it is essential to consider the specific application requirements, including load characteristics and environmental conditions. Understanding the nature of the load and the operating environment will help determine the appropriate type and size of the capacitor.

B. Performance Specifications

Key performance specifications, such as capacitance value and voltage rating, must be evaluated to ensure the selected shunt capacitor meets the system's needs. Proper sizing is crucial to avoid issues such as overvoltage or insufficient reactive power support.

C. Regulatory Standards

Compliance with industry standards and regulations is vital when selecting shunt capacitors. Ensuring that the capacitors meet relevant certifications guarantees their safety and reliability in electrical systems.

VII. Conclusion

In conclusion, shunt capacitors are critical components in electrical systems, providing essential functions such as power factor correction, voltage stabilization, and harmonic filtering. Understanding the various product categories, including types, materials, and voltage ratings, is crucial for selecting the right shunt capacitor for specific applications. As technology continues to evolve, future trends in shunt capacitor technology will likely focus on improving efficiency, reliability, and adaptability to meet the growing demands of modern electrical systems.

VIII. References

For further information on shunt capacitors, consider exploring the following resources:

1. IEEE Standards for Capacitors

2. "Power Factor Correction: A Guide to the Basics" by John Smith

3. Manufacturer datasheets and technical specifications for various shunt capacitors

By understanding the important product categories of shunt capacitors, engineers and technicians can make informed decisions that enhance the performance and reliability of electrical systems.