What are the purchasing models of the latest power capacitor equipment components?

Purchasing Models of the Latest Power Capacitor Equipment Components

I. Introduction

Power capacitors are essential components in electrical systems, playing a critical role in improving power quality, enhancing system efficiency, and ensuring the stability of electrical networks. These devices store electrical energy and release it when needed, making them vital for applications ranging from power factor correction to energy storage. As the demand for reliable and efficient electrical systems grows, understanding the purchasing models for power capacitor equipment components becomes increasingly important for manufacturers, engineers, and procurement professionals.

In this blog post, we will explore the various purchasing models available in the power capacitor industry, the types of components available, factors influencing purchasing decisions, and future trends that may shape the market.

II. Types of Power Capacitor Equipment Components

A. Fixed Capacitors

Fixed capacitors are designed to provide a constant capacitance value and are widely used in power factor correction applications. They are typically employed in industrial settings to improve the power factor of electrical systems, thereby reducing energy costs and enhancing system performance. Key manufacturers of fixed capacitors include companies like Siemens, ABB, and Schneider Electric.

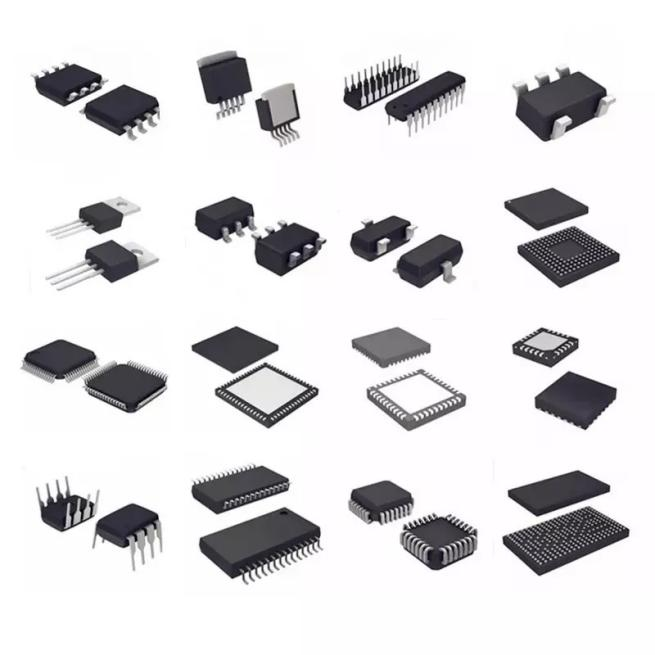

B. Variable Capacitors

Variable capacitors allow for adjustable capacitance values, making them suitable for applications where tuning is necessary. These capacitors are often used in radio frequency applications and in systems requiring fine-tuning of electrical parameters. Leading manufacturers in this category include Vishay and KEMET.

C. Power Factor Correction Capacitors

Power factor correction capacitors are specifically designed to improve the power factor of electrical systems. By reducing reactive power, these capacitors help to lower energy costs and improve the efficiency of electrical systems. Major players in this market include Eaton and Nissin Electric.

D. Specialty Capacitors

Specialty capacitors are designed for specific applications, such as high-voltage environments or unique industrial processes. These capacitors may include film capacitors, ceramic capacitors, and electrolytic capacitors. Manufacturers like Murata and Cornell Dubilier specialize in producing these types of capacitors.

III. Purchasing Models in the Power Capacitor Industry

A. Direct Purchase Model

The direct purchase model involves buying power capacitors directly from manufacturers. This model allows for better pricing and direct communication with the supplier. However, it may require more effort in terms of logistics and inventory management. The advantages of this model include cost savings and direct access to technical support, while disadvantages may include limited flexibility and higher upfront costs.

B. Distributor Model

Distributors play a crucial role in the power capacitor supply chain by acting as intermediaries between manufacturers and end-users. They provide a wide range of products and can offer valuable insights into market trends and product availability. The benefits of using distributors include reduced lead times, access to a broader product range, and simplified purchasing processes.

C. Online Marketplaces

The rise of e-commerce has transformed the purchasing landscape for power capacitors. Online marketplaces allow buyers to compare prices, read reviews, and make informed purchasing decisions from the comfort of their offices. However, while online purchasing offers convenience and often lower prices, it may lack the personalized service and technical support that traditional purchasing methods provide.

D. Contractual Agreements

Long-term supply contracts can provide stability and predictability for both manufacturers and suppliers. These agreements often include negotiated pricing, delivery schedules, and quality assurances. The benefits of contractual relationships include reduced costs, guaranteed supply, and stronger partnerships between buyers and suppliers.

E. Just-in-Time (JIT) Purchasing

Just-in-time purchasing is a strategy that aims to reduce inventory costs by ordering components only as they are needed. This model requires close collaboration with suppliers and efficient logistics management. The advantages of JIT purchasing include reduced inventory holding costs and increased responsiveness to market changes.

IV. Factors Influencing Purchasing Decisions

A. Cost Considerations

Cost is a primary factor influencing purchasing decisions in the power capacitor industry. Buyers must weigh the initial investment against long-term savings, considering factors such as energy efficiency and maintenance costs. The total cost of ownership (TCO) is a critical metric that encompasses not only the purchase price but also operational costs over the product's lifespan.

B. Quality and Reliability

Quality and reliability are paramount in the selection of power capacitors. Buyers often look for products that meet industry standards and certifications, as these factors directly impact system performance and longevity. High-quality capacitors can lead to fewer failures and reduced maintenance costs, making them a wise investment.

C. Supplier Reputation and Support

The reputation of suppliers plays a significant role in purchasing decisions. Buyers often evaluate supplier credentials, including their experience, customer reviews, and after-sales support. A reliable supplier can provide valuable technical assistance and ensure timely delivery, which is crucial for maintaining operational efficiency.

D. Technological Advancements

Technological advancements in power capacitor design and manufacturing can influence purchasing choices. Innovations such as improved materials, enhanced energy efficiency, and smart capacitor technologies are reshaping the market. Buyers must stay informed about these trends to make informed decisions that align with their operational needs.

V. Case Studies

A. Successful Implementation of Purchasing Models

1. **Direct Purchase Example**: A large manufacturing company opted for a direct purchase model to acquire fixed capacitors for their production line. By negotiating directly with the manufacturer, they secured favorable pricing and received tailored technical support, resulting in significant cost savings and improved system performance.

2. **Distributor Utilization Example**: An energy utility company relied on a distributor to source power factor correction capacitors. The distributor provided a wide range of products and facilitated quick delivery, allowing the utility to implement upgrades efficiently and enhance their service reliability.

B. Lessons Learned from Purchasing Decisions

1. **Common Pitfalls**: One common pitfall in purchasing decisions is failing to consider the total cost of ownership. Companies that focus solely on initial costs may overlook long-term savings associated with higher-quality products.

2. **Best Practices**: Establishing strong relationships with suppliers and conducting thorough market research can lead to more informed purchasing decisions. Companies should also prioritize quality and reliability to avoid costly failures in the future.

VI. Future Trends in Power Capacitor Purchasing Models

A. Shift Towards Sustainable Practices

As environmental concerns grow, there is a noticeable shift towards sustainable practices in the power capacitor industry. Eco-friendly capacitor options are becoming more prevalent, and regulations are increasingly influencing purchasing decisions. Companies that prioritize sustainability may gain a competitive edge in the market.

B. Digital Transformation in Purchasing

The digital transformation of purchasing processes is reshaping the power capacitor market. The integration of AI and data analytics can enhance decision-making, streamline procurement processes, and improve inventory management. E-commerce platforms are also expected to play a more significant role in the future, providing buyers with greater access to products and information.

C. Global Supply Chain Considerations

Geopolitical factors and global supply chain disruptions have highlighted the need for robust supply chain management strategies. Companies must develop contingency plans to mitigate risks associated with sourcing components from different regions. Diversifying suppliers and investing in local manufacturing capabilities can enhance resilience in the face of uncertainty.

VII. Conclusion

In conclusion, the purchasing models for power capacitor equipment components are diverse and evolving. Understanding the various types of capacitors, purchasing models, and factors influencing decisions is crucial for manufacturers and procurement professionals. As the industry continues to adapt to technological advancements and sustainability trends, choosing the right purchasing model will be essential for ensuring operational efficiency and long-term success.

By staying informed about market trends and best practices, companies can make strategic purchasing decisions that align with their goals and contribute to a more sustainable and efficient electrical system.

VIII. References

1. Academic Journals

2. Industry Reports

3. Manufacturer Websites

4. Relevant Books and Articles

This blog post provides a comprehensive overview of the purchasing models of the latest power capacitor equipment components, offering insights into the industry and guidance for making informed purchasing decisions.