When will the new aluminum electrolytic capacitors be released?

When Will the New Aluminum Electrolytic Capacitors Be Released?

I. Introduction

Aluminum electrolytic capacitors are essential components in a wide range of electronic circuits, playing a crucial role in energy storage, filtering, and signal coupling. These capacitors are favored for their high capacitance values and relatively low cost, making them indispensable in various applications, from consumer electronics to automotive systems. This article aims to explore the anticipated release timeline of new aluminum electrolytic capacitors, shedding light on the factors influencing their development and the innovations on the horizon.

II. Overview of Aluminum Electrolytic Capacitors

A. Basic Structure and Function

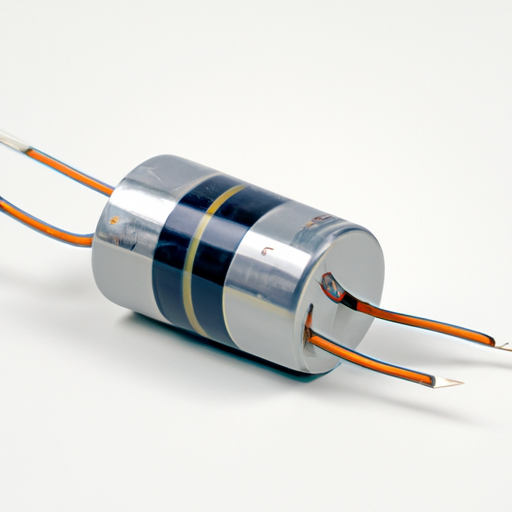

Aluminum electrolytic capacitors consist of two conductive plates, an anode and a cathode, separated by an electrolyte. The anode is typically made of aluminum foil, which is oxidized to form a thin layer of aluminum oxide that acts as the dielectric. The cathode is usually a liquid or gel electrolyte that allows for the flow of ions, enabling the capacitor to store and release electrical energy.

B. Types of Aluminum Electrolytic Capacitors

There are several types of aluminum electrolytic capacitors, each designed for specific applications:

1. **Standard Capacitors**: These are the most common type, used in general-purpose applications.

2. **Low-ESR Capacitors**: Designed for high-frequency applications, these capacitors have a lower equivalent series resistance (ESR), improving efficiency and performance.

3. **High-Temperature Capacitors**: These capacitors can operate in elevated temperature environments, making them suitable for automotive and industrial applications.

C. Applications in Various Industries

Aluminum electrolytic capacitors find applications across multiple sectors:

1. **Consumer Electronics**: Used in devices like televisions, computers, and smartphones for power supply filtering and energy storage.

2. **Automotive**: Essential for power management systems, audio systems, and electronic control units in vehicles.

3. **Industrial Machinery**: Employed in motor drives, power supplies, and automation systems to ensure stable operation.

III. Current Market Trends

A. Demand for Aluminum Electrolytic Capacitors

The demand for aluminum electrolytic capacitors is on the rise, driven by several factors:

1. **Growth in Consumer Electronics**: As technology advances, the need for efficient and compact electronic components increases, leading to higher demand for capacitors.

2. **Rise of Electric Vehicles**: The automotive industry's shift towards electric vehicles (EVs) has created a surge in demand for capacitors that can handle high power and energy storage requirements.

B. Technological Advancements

Recent technological advancements have significantly impacted the aluminum electrolytic capacitor market:

1. **Miniaturization**: Manufacturers are developing smaller capacitors with higher capacitance values, allowing for more compact electronic designs.

2. **Enhanced Performance Characteristics**: Innovations in materials and design have led to capacitors with improved thermal stability, lower ESR, and longer lifespans.

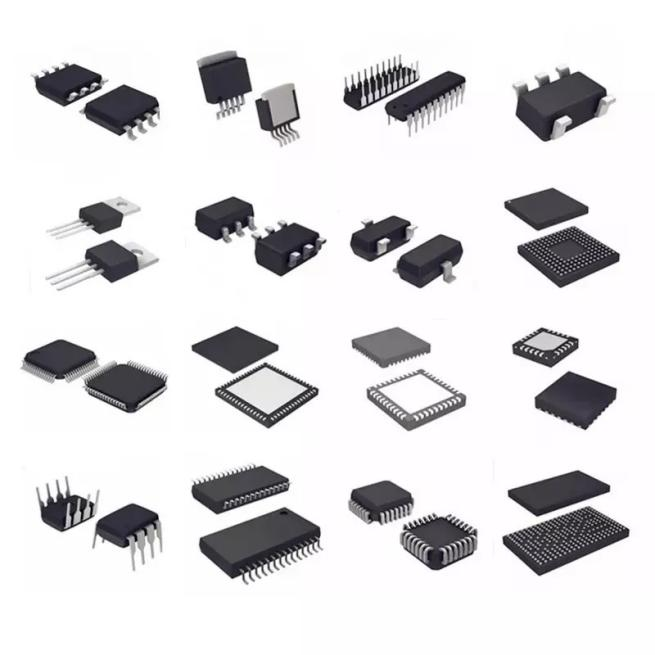

C. Key Players in the Market

The aluminum electrolytic capacitor market is characterized by several key players:

1. **Major Manufacturers**: Companies like Panasonic, Nichicon, and Rubycon dominate the market, offering a wide range of products.

2. **Emerging Companies**: New entrants are also making their mark, focusing on niche applications and innovative designs.

IV. Factors Influencing Release Timelines

A. Research and Development Cycles

The development of new aluminum electrolytic capacitors involves extensive research and development (R&D) cycles:

1. **Innovation in Materials and Design**: Ongoing research into new materials and designs can lead to significant improvements in capacitor performance.

2. **Prototyping and Testing Phases**: Before a new capacitor can be released, it must undergo rigorous testing to ensure reliability and compliance with industry standards.

B. Supply Chain Considerations

The supply chain plays a critical role in determining release timelines:

1. **Raw Material Availability**: The availability of key materials, such as aluminum and electrolytes, can impact production schedules.

2. **Manufacturing Capabilities**: Manufacturers must have the necessary infrastructure and technology to produce new capacitor designs efficiently.

C. Regulatory Approvals

Regulatory approvals are essential for ensuring the safety and environmental compliance of new products:

1. **Safety Standards**: Capacitors must meet specific safety standards to be used in consumer and industrial applications.

2. **Environmental Regulations**: Compliance with environmental regulations is increasingly important, especially as sustainability becomes a priority in manufacturing.

V. Anticipated Release Dates

A. Current Announcements from Manufacturers

Several manufacturers have announced plans to release new aluminum electrolytic capacitors in the coming years. For instance, companies are focusing on developing low-ESR and high-temperature capacitors to meet the growing demands of the automotive and consumer electronics markets.

B. Expected Timelines Based on Industry Trends

Based on current industry trends, it is anticipated that new aluminum electrolytic capacitors will be released within the next 1-2 years. This timeline aligns with the ongoing advancements in technology and the increasing demand for high-performance components.

C. Potential Delays and Their Causes

While the outlook is positive, potential delays could arise from various factors, including:

1. **Supply Chain Disruptions**: Global supply chain issues, such as shortages of raw materials, could hinder production schedules.

2. **Regulatory Hurdles**: Delays in obtaining necessary regulatory approvals could push back release dates.

VI. Future Innovations in Aluminum Electrolytic Capacitors

A. Expected Advancements in Technology

The future of aluminum electrolytic capacitors looks promising, with several expected advancements:

1. **Higher Capacitance Values**: Ongoing research aims to develop capacitors with even higher capacitance values, enabling more efficient energy storage.

2. **Improved Thermal Stability**: Innovations in materials could lead to capacitors that can operate effectively in extreme temperature conditions.

B. Integration with Other Technologies

The integration of aluminum electrolytic capacitors with other technologies is also on the rise:

1. **Hybrid Capacitors**: Combining aluminum electrolytic capacitors with other types of capacitors can enhance performance and efficiency.

2. **Smart Capacitors**: The development of smart capacitors that can monitor and adjust their performance in real-time is an exciting area of research.

C. Sustainability Efforts

Sustainability is becoming increasingly important in the electronics industry:

1. **Eco-Friendly Materials**: Manufacturers are exploring the use of eco-friendly materials in capacitor production to reduce environmental impact.

2. **Recycling Initiatives**: Efforts to improve recycling processes for aluminum electrolytic capacitors are underway, promoting a circular economy.

VII. Conclusion

In summary, aluminum electrolytic capacitors are vital components in modern electronics, and their development is influenced by various factors, including market demand, technological advancements, and regulatory requirements. As manufacturers work towards releasing new and improved capacitors, it is essential for industry stakeholders to stay informed about these developments. The future of aluminum electrolytic capacitors looks bright, with innovations on the horizon that promise to enhance performance, sustainability, and integration with emerging technologies.

VIII. References

1. "Aluminum Electrolytic Capacitors: A Comprehensive Guide." Electronics Weekly.

2. "The Future of Capacitors: Trends and Innovations." IEEE Spectrum.

3. Manufacturer announcements from Panasonic, Nichicon, and Rubycon.

4. "Sustainability in Electronics Manufacturing." Journal of Cleaner Production.

By keeping an eye on these trends and developments, professionals in the electronics industry can better prepare for the changes and opportunities that lie ahead in the world of aluminum electrolytic capacitors.