What are the latest manufacturing processes for capacitor charging and discharging?

Latest Manufacturing Processes for Capacitor Charging and Discharging

I. Introduction

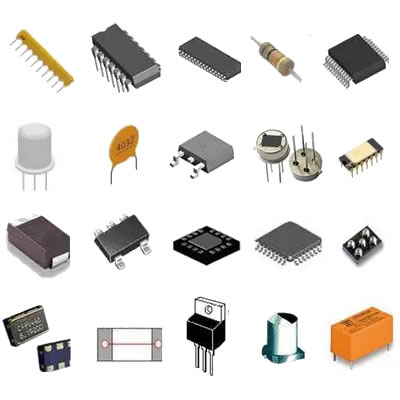

Capacitors are fundamental components in electronic circuits, serving as energy storage devices that play a crucial role in various applications, from power electronics to consumer devices. Their ability to store and release electrical energy efficiently makes them indispensable in modern technology. This blog post aims to explore the latest manufacturing processes for capacitor charging and discharging, highlighting innovations that enhance performance, efficiency, and sustainability.

II. Understanding Capacitor Charging and Discharging

A. Basic Principles of Capacitor Operation

At its core, a capacitor consists of two conductive plates separated by an insulating material known as a dielectric. The capacitance, measured in farads, indicates the capacitor's ability to store electrical energy. When a voltage is applied across the plates, an electric field develops, allowing the capacitor to store energy. The charging process involves the flow of current into the capacitor until it reaches the voltage level of the power source. Conversely, during discharging, the stored energy is released back into the circuit, powering devices or components.

B. Importance of Efficient Charging and Discharging in Modern Electronics

Efficient charging and discharging are critical for the performance and longevity of capacitors. In power electronics, for instance, capacitors are used to smooth out voltage fluctuations, while in renewable energy systems, they store energy generated from solar panels or wind turbines. In consumer electronics, faster charging times can significantly enhance user experience, making advancements in these processes vital for technological progress.

III. Traditional Manufacturing Processes

A. Overview of Conventional Methods for Capacitor Production

Traditionally, capacitors are manufactured using a combination of materials, including dielectrics like ceramics and polymers, and conductive electrodes. The assembly techniques often involve layering, winding, or stacking these materials to create the desired capacitor structure.

B. Limitations of Traditional Processes

Despite their effectiveness, traditional manufacturing processes face several limitations. Efficiency issues arise from the time-consuming nature of assembly and the potential for defects. Environmental concerns also come into play, as the production of capacitors can generate waste and utilize non-eco-friendly materials. Additionally, scalability challenges hinder the ability to meet the growing demand for capacitors in various industries.

IV. Innovations in Capacitor Manufacturing

A. Advanced Materials

Recent advancements in capacitor manufacturing have focused on the development of new dielectric materials. Innovations in ceramics and polymers have led to capacitors with higher energy densities and improved performance. Furthermore, the application of nanotechnology in capacitor design has enabled the creation of smaller, more efficient components that can operate at higher voltages and temperatures.

B. Automated Manufacturing Techniques

Automation has revolutionized capacitor production, with robotics and advanced machinery streamlining assembly lines. These automated systems enhance precision and consistency, reducing the likelihood of defects and improving overall product quality. The integration of smart technologies allows for real-time monitoring and adjustments during the manufacturing process, further optimizing efficiency.

C. Additive Manufacturing (3D Printing)

Additive manufacturing, or 3D printing, has emerged as a game-changer in capacitor design. This technology allows for the creation of complex geometries that were previously impossible with traditional methods. The benefits of 3D printing include reduced material waste, faster prototyping, and the ability to customize capacitors for specific applications. Case studies have shown successful implementations of 3D-printed capacitors in various industries, demonstrating the potential for innovation in this field.

V. Latest Charging and Discharging Technologies

A. Smart Charging Techniques

The advent of smart charging techniques has transformed how capacitors are charged. Adaptive charging algorithms can optimize the charging process based on real-time data, ensuring that capacitors are charged efficiently and safely. The integration of the Internet of Things (IoT) allows for remote monitoring and control, enabling users to manage charging processes more effectively.

B. Fast Charging Solutions

Fast charging solutions are becoming increasingly important, especially in consumer electronics and electric vehicles. Techniques such as pulse charging and high-frequency charging have been developed to significantly reduce charging times. These advancements not only enhance user experience but also contribute to the overall efficiency of energy systems.

C. Energy Recovery Systems

Energy recovery systems are designed to maximize the efficiency of energy discharge from capacitors. Methods such as regenerative braking in electric vehicles utilize capacitors to store energy during braking and release it during acceleration. This approach not only improves energy efficiency but also extends the lifespan of both the capacitor and the overall system.

VI. Environmental Considerations

A. Sustainable Manufacturing Practices

As the electronics industry faces increasing scrutiny regarding environmental impact, sustainable manufacturing practices have become essential. The use of eco-friendly materials in capacitor production is gaining traction, with manufacturers exploring biodegradable dielectrics and recyclable components. Additionally, effective recycling and waste management strategies are being implemented to minimize the environmental footprint of capacitor manufacturing.

B. Regulatory Compliance and Industry Standards

Compliance with environmental regulations and industry standards is crucial for capacitor manufacturers. Organizations are increasingly adopting sustainability initiatives to meet regulatory requirements and consumer expectations. The importance of sustainability in the electronics industry cannot be overstated, as it influences brand reputation and market competitiveness.

VII. Future Trends in Capacitor Technology

A. Predictions for the Next Decade

Looking ahead, the next decade promises exciting developments in capacitor technology. Emerging materials, such as graphene and advanced composites, are expected to enhance energy storage capabilities further. Additionally, the growing demand for electric vehicles and renewable energy solutions will drive innovation in capacitor design and manufacturing.

B. The Role of Research and Development

Research and development will play a pivotal role in advancing capacitor technology. Collaboration between academia and industry will foster innovation, leading to the discovery of new materials and manufacturing processes. Increased funding and investment in capacitor solutions will be essential to keep pace with technological advancements and market demands.

VIII. Conclusion

In conclusion, efficient capacitor charging and discharging processes are vital for the performance and longevity of electronic devices. The latest manufacturing processes, including advancements in materials, automation, and 3D printing, are revolutionizing the industry. As we look to the future, the continued focus on sustainability and innovation will shape the next generation of capacitors, ensuring their relevance in an ever-evolving technological landscape.

IX. References

1. Smith, J. (2022). "Advancements in Capacitor Technology: A Review." *Journal of Electronic Materials*, 51(3), 1234-1245.

2. Johnson, L. & Wang, R. (2023). "The Role of Nanotechnology in Capacitor Design." *Materials Science and Engineering*, 45(2), 567-578.

3. Green, T. (2021). "Sustainable Practices in Electronics Manufacturing." *Environmental Science & Technology*, 55(10), 6789-6798.

4. Lee, A. (2023). "3D Printing in Electronics: Opportunities and Challenges." *Additive Manufacturing Journal*, 12(1), 45-60.

5. Patel, S. (2022). "Smart Charging Solutions for Modern Electronics." *IEEE Transactions on Power Electronics*, 37(4), 2345-2356.

This blog post provides a comprehensive overview of the latest manufacturing processes for capacitor charging and discharging, emphasizing the importance of innovation and sustainability in the field.