What components and modules does a capacitor film contain?

What Components and Modules Does a Capacitor Film Contain?

I. Introduction

Capacitor films are essential components in modern electronics, playing a crucial role in energy storage, filtering, and signal processing. These devices, often referred to as film capacitors, utilize a thin dielectric film to separate conductive plates, allowing them to store electrical energy. Understanding the components and modules that make up capacitor films is vital for engineers, designers, and hobbyists alike, as it influences the performance and application of these components in various electronic circuits. This article will delve into the structure, components, and modules of film capacitors, providing a comprehensive overview of their significance in the electronics industry.

II. Basic Principles of Capacitors

A. Definition of a Capacitor

A capacitor is a passive electronic component that stores electrical energy in an electric field. It consists of two conductive plates separated by an insulating material known as a dielectric. When a voltage is applied across the plates, an electric field is created, allowing the capacitor to store charge.

B. How Capacitors Work

1. **Charge Storage**: Capacitors store electrical energy by accumulating charge on their plates. The amount of charge a capacitor can store is directly proportional to the voltage applied and the capacitance value, which is determined by the surface area of the plates and the properties of the dielectric material.

2. **Electric Field Generation**: When a voltage is applied, an electric field is generated between the plates, allowing the capacitor to maintain a potential difference even after the voltage source is removed.

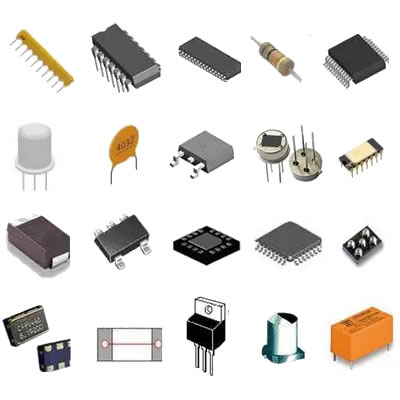

C. Types of Capacitors

Capacitors come in various types, including:

1. **Electrolytic Capacitors**: Known for their high capacitance values, these capacitors use an electrolyte as one of the plates and are polarized, meaning they must be connected in a specific direction.

2. **Ceramic Capacitors**: These capacitors use ceramic materials as the dielectric and are known for their stability and reliability in high-frequency applications.

3. **Film Capacitors**: Utilizing thin plastic films as dielectrics, film capacitors are known for their excellent performance in terms of stability, low loss, and high voltage ratings.

III. Structure of Film Capacitors

A. Dielectric Material

1. **Types of Dielectric Materials Used**:

- **Polyester**: Commonly used for its good electrical properties and cost-effectiveness.

- **Polypropylene**: Known for its low dielectric losses and high insulation resistance, making it suitable for high-frequency applications.

- **Polycarbonate**: Offers excellent thermal stability and is used in applications requiring high reliability.

2. **Role of Dielectric in Capacitor Functionality**: The dielectric material is crucial for the capacitor's performance, as it determines the capacitance value, voltage rating, and temperature stability. A higher dielectric constant allows for greater charge storage in a smaller volume.

B. Electrodes

1. **Types of Electrodes**:

- **Metal Foil Electrodes**: Made from thin sheets of metal, these electrodes provide a large surface area for charge storage.

- **Metalized Film Electrodes**: In this design, a thin layer of metal is deposited onto the dielectric film, allowing for a more compact design.

2. **Function of Electrodes in Charge Storage**: Electrodes are responsible for collecting and storing the charge. The choice of electrode material and design significantly impacts the capacitor's performance characteristics.

C. Construction Techniques

1. **Winding**: In this method, the dielectric and electrodes are wound together to form a cylindrical shape, optimizing space and enhancing performance.

2. **Stacking**: This technique involves stacking layers of dielectric and electrodes, which can increase capacitance but may also affect the overall size and weight.

3. **Laminating**: Laminating involves bonding multiple layers of dielectric and electrodes together, providing a robust structure and improved electrical performance.

IV. Components of a Film Capacitor

A. Dielectric Layer

1. **Thickness and Its Impact on Capacitance**: The thickness of the dielectric layer directly affects the capacitance value. Thinner dielectrics allow for higher capacitance but may compromise voltage ratings.

2. **Temperature Stability**: The dielectric material's ability to maintain performance across a range of temperatures is crucial for reliability in various applications.

B. Electrodes

1. **Conductivity and Material Selection**: The choice of electrode material, such as aluminum or copper, affects the capacitor's conductivity and overall performance.

2. **Surface Area Considerations**: A larger surface area enhances charge storage capacity, making electrode design a critical factor in capacitor performance.

C. Insulation and Encapsulation

1. **Purpose of Insulation**: Insulation prevents electrical leakage and protects the capacitor from environmental factors, ensuring longevity and reliability.

2. **Common Materials Used for Encapsulation**: Common encapsulation materials include epoxy resins and thermoplastics, which provide mechanical protection and environmental resistance.

D. Terminals and Leads

1. **Types of Terminals**: Terminals can be axial or radial, depending on the application and mounting requirements.

2. **Importance of Connection Quality**: High-quality connections are essential for minimizing resistance and ensuring reliable performance in electronic circuits.

V. Modules and Variants of Film Capacitors

A. Types of Film Capacitor Modules

1. **Single-Layer Capacitors**: These capacitors consist of a single layer of dielectric and electrodes, offering simplicity and cost-effectiveness.

2. **Multi-Layer Capacitors**: By stacking multiple layers, these capacitors achieve higher capacitance values in a compact form factor.

B. Specialized Film Capacitors

1. **High-Voltage Capacitors**: Designed to handle high voltage applications, these capacitors use thicker dielectrics and robust construction techniques.

2. **Power Capacitors**: These capacitors are optimized for power applications, providing high capacitance and low equivalent series resistance (ESR).

3. **Audio Capacitors**: Tailored for audio applications, these capacitors are designed to minimize distortion and enhance sound quality.

C. Applications of Different Modules

1. **Consumer Electronics**: Film capacitors are widely used in devices such as televisions, computers, and smartphones for filtering and energy storage.

2. **Industrial Applications**: In industrial settings, film capacitors are used in motor drives, power supplies, and automation systems.

3. **Renewable Energy Systems**: Film capacitors play a vital role in solar inverters and wind turbine systems, helping to manage energy flow and improve efficiency.

VI. Performance Characteristics

A. Capacitance Value

The capacitance value indicates the amount of charge a capacitor can store and is a critical parameter in circuit design.

B. Voltage Rating

The voltage rating specifies the maximum voltage the capacitor can handle without risk of breakdown, ensuring safe operation in various applications.

C. Temperature Coefficient

The temperature coefficient indicates how capacitance changes with temperature, affecting performance in varying environmental conditions.

D. Equivalent Series Resistance (ESR)

ESR is a measure of the resistance encountered by the current flowing through the capacitor, impacting efficiency and heat generation.

E. Lifetime and Reliability

The expected lifetime and reliability of a film capacitor are influenced by factors such as temperature, voltage, and operating conditions, making it essential to choose the right capacitor for specific applications.

VII. Manufacturing Process of Film Capacitors

A. Material Selection

Choosing the right materials for the dielectric and electrodes is crucial for achieving desired performance characteristics.

B. Dielectric Film Production

The production of dielectric films involves processes such as extrusion or casting, ensuring uniform thickness and quality.

C. Electrode Application

Electrodes are applied using techniques like vacuum deposition or lamination, ensuring strong adhesion and optimal performance.

D. Assembly Techniques

Assembly methods, including winding and stacking, are employed to create the final capacitor structure.

E. Quality Control Measures

Rigorous quality control measures are implemented throughout the manufacturing process to ensure reliability and performance standards are met.

VIII. Conclusion

In summary, understanding the components and modules of capacitor films is essential for anyone involved in electronics design and application. From the dielectric materials to the electrode configurations, each element plays a vital role in determining the performance and reliability of film capacitors. As technology advances, the demand for more efficient and reliable capacitors continues to grow, paving the way for innovations in film capacitor technology. By grasping the intricacies of these components, engineers and designers can make informed decisions that enhance the performance of their electronic systems.

IX. References

- Academic Journals

- Industry Standards

- Manufacturer Specifications

This comprehensive overview of capacitor films highlights their importance in electronics and provides insights into their structure, components, and applications. Understanding these elements is crucial for optimizing designs and ensuring the reliability of electronic devices.