What is the mainstream DC resistor production process?

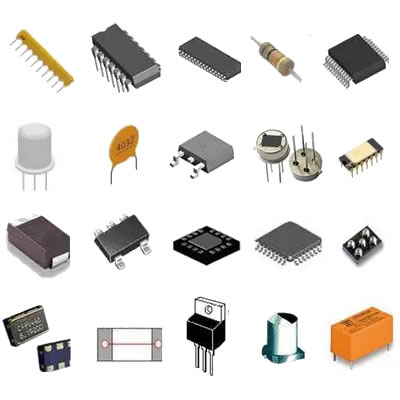

The mainstream DC resistor production process is an important electronic component production process, which plays a vital role in electronic equipment. A DC resistor is an electronic component used to limit current. Its main function is to limit the current within a specific range to protect other components in the circuit from being damaged by excessive current. The production process of DC resistors includes material selection, manufacturing process, testing and packaging. Below we will introduce the production process of mainstream DC resistors in detail.

Secondly, the manufacturing process of DC resistors includes material processing, molding, welding and debugging. The first is material processing, cutting, molding and processing the selected resistor materials and conductor materials to form the basic structure of the resistor. Then there is welding, welding the resistor materials and conductor materials together to form the circuit structure of the resistor. Next is debugging, testing the resistors with test instruments to ensure that their resistance value and stability meet the requirements. Finally, packaging, packaging the debugged resistors for transportation and sales.

Finally, the production process of DC resistors also includes quality control and environmental protection requirements. During the production process, manufacturers need to strictly control the quality of each link to ensure that the performance and stability of the resistors meet the requirements. At the same time, manufacturers also need to comply with environmental protection laws and regulations, take environmental protection measures, and reduce pollution to the environment.

In general, the production process of mainstream DC resistors is a complex process, which requires manufacturers to have advanced production equipment and technology, strictly control the quality of each link, and ensure the performance and stability of the product. Only in this way can high-quality DC resistors be produced to meet the needs of electronic equipment. I hope that through the introduction of this article, readers will have a deeper understanding of the production process of mainstream DC resistors.

The mainstream DC resistor production process is an important electronic component production process, which plays a vital role in electronic equipment. A DC resistor is an electronic component used to limit current. Its main function is to limit the current within a specific range to protect other components in the circuit from being damaged by excessive current. The production process of DC resistors includes material selection, manufacturing process, testing and packaging. Below we will introduce the production process of mainstream DC resistors in detail.

Secondly, the manufacturing process of DC resistors includes material processing, molding, welding and debugging. The first is material processing, cutting, molding and processing the selected resistor materials and conductor materials to form the basic structure of the resistor. Then there is welding, welding the resistor materials and conductor materials together to form the circuit structure of the resistor. Next is debugging, testing the resistors with test instruments to ensure that their resistance value and stability meet the requirements. Finally, packaging, packaging the debugged resistors for transportation and sales.

Finally, the production process of DC resistors also includes quality control and environmental protection requirements. During the production process, manufacturers need to strictly control the quality of each link to ensure that the performance and stability of the resistors meet the requirements. At the same time, manufacturers also need to comply with environmental protection laws and regulations, take environmental protection measures, and reduce pollution to the environment.

In general, the production process of mainstream DC resistors is a complex process, which requires manufacturers to have advanced production equipment and technology, strictly control the quality of each link, and ensure the performance and stability of the product. Only in this way can high-quality DC resistors be produced to meet the needs of electronic equipment. I hope that through the introduction of this article, readers will have a deeper understanding of the production process of mainstream DC resistors.