What are the advantages of ceramic capacitor products?

What are the Advantages of Ceramic Capacitor Products?

I. Introduction

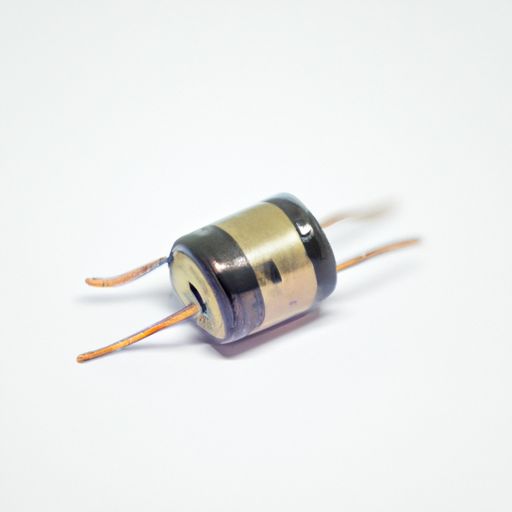

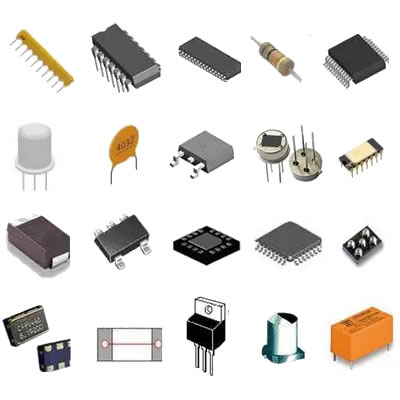

Capacitors are essential components in electronic circuits, serving as energy storage devices that help regulate voltage and current. Among the various types of capacitors available, ceramic capacitors have gained significant popularity due to their unique properties and advantages. This article will explore the advantages of ceramic capacitor products, highlighting their characteristics, applications, and how they compare to other capacitor types.

II. Types of Ceramic Capacitors

Ceramic capacitors are primarily categorized into two classes: Class 1 and Class 2, each with distinct characteristics and applications.

A. Class 1 Ceramic Capacitors

Class 1 ceramic capacitors are known for their stability and low losses. They typically use materials like titanium dioxide, which provides excellent temperature stability and low dielectric absorption.

1. **Characteristics**: Class 1 capacitors exhibit a linear capacitance change with temperature and voltage, making them suitable for precision applications. They have a high Q factor, indicating low energy loss.

2. **Applications**: These capacitors are commonly used in timing circuits, filters, and resonators, where accuracy and stability are paramount.

B. Class 2 Ceramic Capacitors

Class 2 ceramic capacitors, on the other hand, are designed for higher capacitance values and are made from materials like barium titanate.

1. **Characteristics**: While they offer higher capacitance, Class 2 capacitors have a non-linear capacitance change with temperature and voltage, which can affect performance in sensitive applications.

2. **Applications**: These capacitors are widely used in decoupling, bypassing, and coupling applications in consumer electronics and automotive systems.

III. Key Advantages of Ceramic Capacitors

Ceramic capacitors offer several advantages that make them a preferred choice in many electronic applications.

A. High Dielectric Strength

1. **Explanation of Dielectric Strength**: Dielectric strength refers to a material's ability to withstand electric fields without breaking down. Ceramic materials typically have high dielectric strength, allowing them to operate at higher voltages.

2. **Benefits in High-Voltage Applications**: This property makes ceramic capacitors ideal for high-voltage applications, such as power supplies and industrial equipment, where reliability and safety are critical.

B. Temperature Stability

1. **Overview of Temperature Coefficients**: Ceramic capacitors have different temperature coefficients, which indicate how capacitance changes with temperature. Class 1 capacitors have a stable capacitance across a wide temperature range, while Class 2 capacitors may vary.

2. **Performance in Varying Temperature Conditions**: The temperature stability of ceramic capacitors ensures consistent performance in environments with fluctuating temperatures, making them suitable for automotive and industrial applications.

C. Small Size and Lightweight

1. **Comparison with Other Capacitor Types**: Ceramic capacitors are generally smaller and lighter than electrolytic and film capacitors, which can be bulky.

2. **Impact on Circuit Design and Miniaturization**: Their compact size allows for more efficient circuit design and contributes to the miniaturization of electronic devices, which is increasingly important in consumer electronics.

D. Low Equivalent Series Resistance (ESR)

1. **Definition of ESR**: Equivalent Series Resistance (ESR) is a measure of the resistive losses in a capacitor. Low ESR is desirable for efficient energy storage and delivery.

2. **Advantages in High-Frequency Applications**: Ceramic capacitors typically exhibit low ESR, making them ideal for high-frequency applications such as RF circuits and switching power supplies, where energy loss must be minimized.

E. Wide Range of Capacitance Values

1. **Availability of Different Capacitance Ratings**: Ceramic capacitors are available in a broad range of capacitance values, from picofarads to microfarads.

2. **Versatility in Various Applications**: This versatility allows engineers to select the appropriate capacitance for specific applications, whether in filtering, decoupling, or timing circuits.

F. Reliability and Longevity

1. **Resistance to Aging and Environmental Factors**: Ceramic capacitors are less susceptible to aging and environmental factors compared to other types, such as electrolytic capacitors, which can degrade over time.

2. **Implications for Long-Term Use in Devices**: Their reliability and longevity make ceramic capacitors an excellent choice for applications requiring long-term performance, such as automotive and industrial systems.

IV. Applications of Ceramic Capacitors

Ceramic capacitors are used in a wide range of applications across various industries.

A. Consumer Electronics

In consumer electronics, ceramic capacitors are found in smartphones, tablets, and laptops, where they are used for decoupling, filtering, and timing applications. Their small size and reliability make them ideal for compact devices.

B. Automotive Industry

In the automotive sector, ceramic capacitors play a crucial role in electric vehicles and advanced driver-assistance systems (ADAS). They help manage power distribution and signal processing, contributing to the overall efficiency and safety of modern vehicles.

C. Industrial Equipment

Ceramic capacitors are widely used in industrial automation and control systems. Their high reliability and performance in harsh environments make them suitable for applications in manufacturing and process control.

D. Telecommunications

In telecommunications, ceramic capacitors are essential for signal processing and transmission. They help maintain signal integrity and reduce noise, which is critical for effective communication systems.

V. Comparison with Other Capacitor Types

When selecting capacitors for specific applications, it's essential to compare ceramic capacitors with other types.

A. Electrolytic Capacitors

Electrolytic capacitors offer higher capacitance values but are larger and less stable than ceramic capacitors. They are typically used in power supply applications where size is less critical.

B. Film Capacitors

Film capacitors provide excellent stability and low losses but are bulkier than ceramic capacitors. They are often used in audio applications where sound quality is paramount.

C. Tantalum Capacitors

Tantalum capacitors offer high capacitance in a small package but can be more expensive and less reliable than ceramic capacitors. They are often used in applications where size is critical, but the cost may be a concern.

VI. Challenges and Limitations

Despite their many advantages, ceramic capacitors do have some challenges and limitations.

A. Voltage Coefficient

1. **Explanation of Voltage Dependency**: The capacitance of ceramic capacitors can change with applied voltage, particularly in Class 2 capacitors. This voltage coefficient can lead to design challenges.

2. **Impact on Design Choices**: Engineers must consider this factor when designing circuits to ensure that the capacitor will perform as expected under varying voltage conditions.

B. Microphonics

1. **Definition and Implications in Sensitive Applications**: Microphonics refers to the sensitivity of capacitors to mechanical vibrations, which can affect performance in sensitive applications, such as audio equipment.

C. Cost Considerations

1. **Comparison with Other Capacitor Types**: While ceramic capacitors are generally cost-effective, high-capacitance Class 2 capacitors can be more expensive than their electrolytic counterparts, which may influence design decisions.

VII. Conclusion

In summary, ceramic capacitors offer numerous advantages, including high dielectric strength, temperature stability, small size, low ESR, a wide range of capacitance values, and reliability. These properties make them suitable for various applications, from consumer electronics to automotive and industrial systems.

As technology continues to evolve, the demand for smaller, more efficient components will likely drive further advancements in ceramic capacitor technology. Selecting the right capacitor for specific applications is crucial for ensuring optimal performance and reliability in electronic devices.

VIII. References

For further exploration of ceramic capacitors and their applications, consider the following resources:

1. "Capacitor Technology: A Comprehensive Guide" - A detailed overview of various capacitor types and their applications.

2. "Understanding Ceramic Capacitors" - A technical paper discussing the properties and advantages of ceramic capacitors.

3. "The Future of Capacitor Technology" - An article exploring emerging trends and innovations in capacitor design and materials.