Electrolytic capacitor product training precautions

Electrolytic Capacitor Product Training Precautions

I. Introduction

Electrolytic capacitors are essential components in modern electronic devices, playing a crucial role in energy storage, filtering, and signal processing. Understanding their operation, applications, and safety precautions is vital for anyone involved in electronics, from engineers to technicians. This blog post aims to provide a comprehensive overview of electrolytic capacitors, emphasizing the importance of proper training and safety measures.

II. Understanding Electrolytic Capacitors

A. Basic Principles of Operation

Electrolytic capacitors are polarized capacitors that utilize an electrolyte to achieve a larger capacitance value than non-polarized capacitors. Their structure typically consists of two conductive plates separated by an insulating layer, with one plate coated in a thin oxide layer that acts as the dielectric. The electrolyte, which can be liquid or solid, enhances the capacitor's ability to store charge.

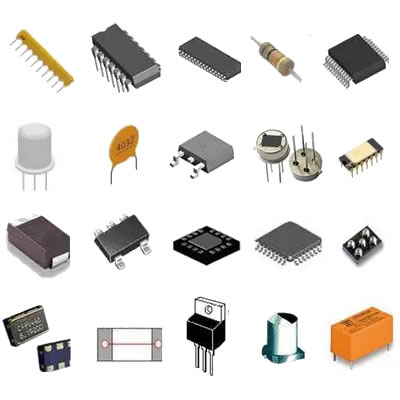

B. Types of Electrolytic Capacitors

1. **Aluminum Electrolytic Capacitors**: These are the most common type, known for their high capacitance and voltage ratings. They are widely used in power supply circuits and audio applications.

2. **Tantalum Electrolytic Capacitors**: Tantalum capacitors offer higher capacitance in a smaller package compared to aluminum capacitors. They are often used in applications requiring stable performance over a wide temperature range.

3. **Other Variants**: There are also hybrid and organic electrolytic capacitors, each designed for specific applications and performance requirements.

C. Common Applications

Electrolytic capacitors are used in various applications, including:

1. **Power Supply Filtering**: They smooth out voltage fluctuations in power supplies, ensuring stable operation of electronic devices.

2. **Signal Coupling and Decoupling**: In audio and RF applications, electrolytic capacitors help couple signals between stages and decouple noise from power lines.

3. **Timing Circuits**: They are integral to timing circuits, where they work with resistors to create time delays.

III. Safety Precautions

A. General Safety Guidelines

Safety is paramount when working with electrolytic capacitors. Here are some general safety guidelines:

1. **Personal Protective Equipment (PPE)**: Always wear appropriate PPE, including safety glasses and gloves, to protect against potential hazards.

2. **Work Environment Considerations**: Ensure that the workspace is clean, well-lit, and free from clutter to minimize the risk of accidents.

B. Handling and Storage

Proper handling and storage of electrolytic capacitors are crucial to prevent damage and ensure safety:

1. **Proper Storage Conditions**: Store capacitors in a cool, dry place, away from direct sunlight and extreme temperatures. This helps maintain their performance and longevity.

2. **Avoiding Physical Damage**: Handle capacitors with care to avoid physical damage, which can lead to failure or leakage.

C. Electrical Safety

Understanding electrical safety is vital when working with electrolytic capacitors:

1. **Understanding Voltage Ratings**: Always be aware of the voltage ratings of capacitors. Exceeding these ratings can lead to catastrophic failure.

2. **Discharge Procedures**: Before handling capacitors, ensure they are fully discharged to prevent electric shock. Use a resistor to safely discharge the capacitor.

3. **Avoiding Short Circuits**: Be cautious when connecting capacitors in circuits to avoid short circuits, which can damage components and pose safety risks.

IV. Training Requirements

A. Target Audience for Training

Training on electrolytic capacitors should target:

1. **Engineers and Technicians**: Those involved in the design, testing, and maintenance of electronic devices.

2. **Quality Control Personnel**: Individuals responsible for ensuring that products meet safety and performance standards.

B. Key Training Topics

Essential topics for training include:

1. **Identification of Capacitor Types**: Understanding the differences between various types of electrolytic capacitors and their applications.

2. **Reading and Interpreting Specifications**: Learning how to read capacitor specifications, including capacitance, voltage rating, and ESR.

3. **Installation and Soldering Techniques**: Proper techniques for installing and soldering capacitors to ensure reliable connections.

C. Importance of Hands-On Training

Hands-on training is crucial for effective learning:

1. **Practical Exercises**: Engaging in practical exercises helps reinforce theoretical knowledge and build confidence in handling capacitors.

2. **Real-World Scenarios**: Training should include real-world scenarios to prepare participants for challenges they may encounter in the field.

V. Common Mistakes and Misconceptions

A. Overvoltage and Its Consequences

One of the most common mistakes is applying a voltage that exceeds the capacitor's rating. This can lead to overheating, leakage, or even explosion. Always check voltage ratings before use.

B. Misunderstanding Capacitance Values

Capacitance values can be confusing, especially when dealing with different units. It's essential to understand the implications of capacitance in circuit design and operation.

C. Ignoring Manufacturer Specifications

Manufacturers provide specifications for a reason. Ignoring these can lead to improper use and potential failure of the capacitor.

D. Improper Disposal of Electrolytic Capacitors

Electrolytic capacitors can contain hazardous materials. Proper disposal methods should be followed to minimize environmental impact.

VI. Quality Control and Testing

A. Importance of Quality Assurance

Quality assurance is critical in ensuring that electrolytic capacitors meet performance and safety standards. Regular testing and inspection can prevent failures in the field.

B. Testing Methods

1. **Capacitance Measurement**: Use capacitance meters to verify that capacitors meet specified values.

2. **Equivalent Series Resistance (ESR) Testing**: ESR testing helps assess the capacitor's efficiency and performance in a circuit.

3. **Leakage Current Testing**: Measuring leakage current can indicate potential failures and help ensure reliability.

C. Documentation and Reporting

Maintaining accurate documentation of testing results is essential for quality control and compliance with industry standards.

VII. Regulatory Compliance

A. Understanding Relevant Standards

Compliance with industry standards is crucial for product safety and marketability:

1. **RoHS Compliance**: Ensures that products are free from hazardous substances.

2. **UL and CE Marking**: Indicates that products meet safety and performance standards.

B. Importance of Compliance in Product Development

Adhering to regulatory standards not only ensures safety but also enhances the credibility of the product in the market.

VIII. Conclusion

In conclusion, understanding electrolytic capacitors and the precautions necessary for their safe handling and use is essential for anyone involved in electronics. Proper training, adherence to safety guidelines, and awareness of common mistakes can significantly reduce risks and enhance product reliability. Continuous education and improvement in practices will ensure that professionals remain competent in this ever-evolving field.

IX. References

For further reading and resources, consider the following:

1. **Suggested Reading Materials**: Books and articles on capacitor technology and applications.

2. **Relevant Industry Standards and Guidelines**: Documentation from organizations like IEC and IEEE.

3. **Online Resources for Further Learning**: Websites and online courses dedicated to electronics and capacitor technology.

By following these guidelines and investing in proper training, individuals and organizations can ensure the safe and effective use of electrolytic capacitors in their applications.