What is the production process of mainstream resistor rt54?

What is the Production Process of Mainstream Resistor RT54?

I. Introduction

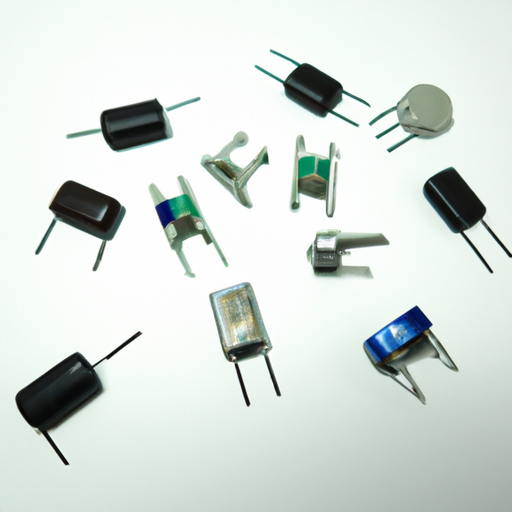

Resistors are fundamental components in electronic circuits, serving the crucial role of controlling the flow of electric current. They are essential for ensuring that devices operate safely and effectively, making them indispensable in a wide range of applications. Among the various types of resistors available, the RT54 resistor stands out due to its reliability and versatility. This article aims to explore the production process of the RT54 resistor, shedding light on the materials, manufacturing steps, and quality control measures that contribute to its performance.

II. Understanding Resistors

A. Basic Principles of Resistance

At the heart of every resistor lies the principle of resistance, which is defined as the opposition to the flow of electric current. This relationship is governed by Ohm's Law, which states that the current (I) flowing through a conductor between two points is directly proportional to the voltage (V) across the two points and inversely proportional to the resistance (R). The formula is expressed as:

\[ V = I \times R \]

Resistors can be categorized into various types, including fixed resistors, which have a constant resistance value, and variable resistors, which allow for adjustable resistance.

B. Characteristics of Resistors

The performance of a resistor is defined by several key characteristics:

1. **Resistance Value**: This is the measure of how much the resistor opposes current flow, typically expressed in ohms (Ω).

2. **Tolerance**: This indicates the precision of the resistor's resistance value, usually expressed as a percentage. A lower tolerance means higher accuracy.

3. **Power Rating**: This defines the maximum amount of power the resistor can dissipate without being damaged, measured in watts (W).

C. Importance of Quality and Reliability in Resistors

In electronic circuits, the quality and reliability of resistors are paramount. A resistor that fails can lead to circuit malfunctions, potentially damaging other components. Therefore, manufacturers must adhere to strict quality control measures throughout the production process.

III. Overview of the RT54 Resistor

A. Specifications of the RT54 Resistor

The RT54 resistor is known for its robust specifications, which include:

1. **Resistance Range**: Typically available in a wide range of resistance values, making it suitable for various applications.

2. **Tolerance Levels**: The RT54 offers different tolerance levels, allowing designers to select the appropriate resistor for their specific needs.

3. **Power Ratings**: With power ratings that cater to both low and high-power applications, the RT54 is versatile enough for many uses.

B. Common Applications of the RT54 Resistor

The RT54 resistor finds its applications in numerous fields, including:

1. **Consumer Electronics**: Used in devices such as televisions, smartphones, and computers.

2. **Industrial Applications**: Employed in machinery and control systems where precise resistance is crucial.

3. **Automotive Uses**: Integral to various automotive systems, ensuring reliable performance in vehicles.

IV. Raw Materials Used in RT54 Production

A. Conductive Materials

The performance of the RT54 resistor is heavily influenced by the materials used in its construction. Key conductive materials include:

1. **Carbon Composition**: Often used for its stability and cost-effectiveness.

2. **Metal Film**: Provides high precision and low noise, making it ideal for sensitive applications.

3. **Thick Film**: Commonly used for surface-mounted resistors, offering durability and reliability.

B. Insulating Materials

Insulating materials are equally important in resistor production, ensuring that the conductive elements function correctly without interference. These include:

1. **Ceramic Substrates**: Provide excellent thermal stability and electrical insulation.

2. **Epoxy Coatings**: Protect the resistor from environmental factors and mechanical stress.

C. Other Materials

Additional materials used in the production of RT54 resistors include:

1. **Lead Frames**: Essential for connecting the resistor to the circuit.

2. **Protective Coatings**: Applied to enhance durability and resistance to environmental factors.

V. The Production Process of RT54 Resistors

A. Design and Engineering

The production of RT54 resistors begins with design and engineering. Initial design considerations involve determining the specifications required for the intended application. Engineers use simulation software to model the resistor's performance under various conditions, allowing for optimization before physical production begins.

B. Material Preparation

Once the design is finalized, the next step is material preparation. This involves sourcing high-quality raw materials and conducting rigorous quality control checks to ensure they meet industry standards. Conductive and insulating materials are then prepared for the manufacturing process.

C. Manufacturing Steps

The manufacturing of RT54 resistors involves several key steps:

1. **Forming the Resistor Element**:

- **Carbon Composition Mixing**: For carbon composition resistors, the conductive material is mixed with a binder to form a paste.

- **Metal Film Deposition**: In metal film resistors, a thin layer of metal is deposited onto a ceramic substrate using vacuum deposition techniques.

- **Thick Film Printing**: For thick film resistors, a paste containing conductive materials is printed onto the substrate and then cured.

2. **Assembly**:

- **Mounting the Resistor Element on Substrates**: The formed resistor elements are carefully mounted onto the insulating substrates.

- **Adding Lead Frames**: Lead frames are attached to facilitate electrical connections.

3. **Encapsulation**:

- **Application of Protective Coatings**: A protective coating is applied to shield the resistor from environmental damage.

- **Curing Processes**: The encapsulated resistors undergo curing processes to ensure the coatings adhere properly and provide maximum protection.

D. Quality Control

Quality control is a critical aspect of the production process. Each batch of resistors undergoes rigorous testing to ensure they meet specified resistance values and tolerances. Additional tests assess reliability and performance under various conditions. Finally, a thorough inspection is conducted before packaging to ensure that only high-quality resistors reach the market.

VI. Challenges in the Production Process

The production of RT54 resistors is not without its challenges. Manufacturers must navigate several issues, including:

A. Maintaining Consistency in Resistance Values

Achieving consistent resistance values across production batches is crucial for reliability. Variations can arise from material inconsistencies or manufacturing errors.

B. Managing Production Costs

Balancing quality with cost-effectiveness is a constant challenge. Manufacturers must find ways to optimize production processes without compromising on quality.

C. Adapting to Technological Advancements

As technology evolves, so do the demands for resistors. Manufacturers must stay ahead of trends and adapt their production processes accordingly.

D. Environmental Considerations and Regulations

With increasing awareness of environmental issues, manufacturers must comply with regulations regarding waste management and the use of hazardous materials in production.

VII. Future Trends in Resistor Production

The future of resistor production is poised for exciting developments. Key trends include:

A. Innovations in Materials and Technology

Research into new materials and production techniques is ongoing, with the potential to enhance performance and reduce costs.

B. The Impact of Automation and AI in Manufacturing

Automation and artificial intelligence are transforming manufacturing processes, leading to increased efficiency and precision in resistor production.

C. Sustainability Practices in Resistor Production

As sustainability becomes a priority, manufacturers are exploring eco-friendly materials and practices to minimize their environmental impact.

VIII. Conclusion

The RT54 resistor plays a vital role in modern electronics, and understanding its production process provides valuable insights into its reliability and performance. From the careful selection of raw materials to the rigorous quality control measures, each step in the production process is designed to ensure that the RT54 meets the high standards expected by consumers and industries alike. As technology continues to advance, the future of resistor manufacturing looks promising, with innovations that will further enhance the quality and sustainability of these essential components.

IX. References

For further reading on resistors and their production processes, consider exploring the following resources:

1. "Electronic Components: A Complete Reference for Engineers and Technicians" by John Doe.

2. "Resistor Technology: Principles and Applications" by Jane Smith.

3. Industry standards and guidelines from organizations such as the International Electrotechnical Commission (IEC) and the Institute of Electrical and Electronics Engineers (IEEE).