Mainstream non-inductive resistor product series parameters

Mainstream Non-Inductive Resistor Product Series Parameters

I. Introduction

A. Definition of Non-Inductive Resistors

Non-inductive resistors are specialized resistive components designed to minimize or eliminate inductance, which can adversely affect circuit performance, especially in high-frequency applications. Unlike traditional resistors, which may exhibit inductive properties due to their construction, non-inductive resistors are engineered to provide stable resistance without the unwanted inductive reactance.

B. Importance of Non-Inductive Resistors in Electronic Applications

In the realm of electronics, the significance of non-inductive resistors cannot be overstated. They play a crucial role in various applications, including power electronics, audio equipment, and precision measurement devices. By ensuring minimal inductance, these resistors help maintain signal integrity and improve overall circuit performance, making them indispensable in modern electronic designs.

C. Overview of the Article's Purpose and Scope

This article aims to provide a comprehensive overview of mainstream non-inductive resistor product series parameters. We will explore their characteristics, applications, key parameters, types, performance metrics, and selection criteria, equipping readers with the knowledge needed to make informed decisions when choosing non-inductive resistors for their projects.

II. Understanding Non-Inductive Resistors

1. Basic Principles of Operation

Non-inductive resistors operate on the same fundamental principles as standard resistors, providing resistance to the flow of electric current. However, their design minimizes the effects of inductance, which can introduce unwanted phase shifts and signal distortion in high-frequency circuits.

2. Comparison with Inductive Resistors

Inductive resistors, such as traditional wirewound resistors, can store energy in a magnetic field, leading to inductive reactance. This reactance can interfere with the intended operation of circuits, particularly in applications involving rapid signal changes. Non-inductive resistors, on the other hand, are constructed to avoid these issues, ensuring a more predictable and stable performance.

1. Power Electronics

In power electronics, non-inductive resistors are used in applications such as snubber circuits, where they help dissipate energy without introducing inductive effects that could lead to voltage spikes.

2. Audio Equipment

In audio applications, non-inductive resistors are essential for maintaining signal fidelity. They are often used in crossover networks and other audio processing circuits to ensure that sound quality remains uncompromised.

3. Measurement and Testing Equipment

Precision measurement devices rely on non-inductive resistors to provide accurate readings. Their stable resistance characteristics are crucial for calibration and testing, where even minor inductive effects can lead to significant errors.

III. Key Parameters of Non-Inductive Resistors

1. Definition and Measurement

The resistance value of a non-inductive resistor is a measure of its opposition to current flow, typically expressed in ohms (Ω). It is determined using standard measurement techniques, such as ohmmeters.

2. Common Resistance Values in Product Series

Non-inductive resistors are available in a wide range of resistance values, from fractions of an ohm to several megaohms, catering to various applications and circuit requirements.

1. Explanation of Power Rating

The power rating indicates the maximum amount of power a resistor can dissipate without overheating. It is typically expressed in watts (W) and is a critical parameter for ensuring reliable operation.

2. Importance in Circuit Design

Selecting a resistor with an appropriate power rating is essential to prevent thermal failure. Inadequate power ratings can lead to overheating, reduced lifespan, and potential circuit damage.

1. Definition of Tolerance

Tolerance refers to the allowable deviation from the specified resistance value, expressed as a percentage. It indicates the precision of the resistor.

2. Common Tolerance Levels in Non-Inductive Resistors

Non-inductive resistors are available with various tolerance levels, typically ranging from ±1% to ±5%, depending on the application requirements.

1. Explanation of Temperature Coefficient

The temperature coefficient indicates how much the resistance value changes with temperature, typically expressed in parts per million per degree Celsius (ppm/°C).

2. Impact on Performance

A low temperature coefficient is desirable in precision applications, as it ensures that the resistor maintains its specified resistance over a range of operating temperatures.

1. Definition and Importance

The voltage rating specifies the maximum voltage that can be applied across the resistor without risk of breakdown. Exceeding this rating can lead to catastrophic failure.

2. Typical Voltage Ratings in Product Series

Non-inductive resistors come with various voltage ratings, often ranging from a few volts to several kilovolts, depending on their intended use.

1. Common Sizes and Shapes

Non-inductive resistors are available in various sizes and shapes, including axial, radial, and surface-mount configurations, allowing for flexibility in circuit design.

2. Influence on Application and Design

The size and form factor of a resistor can impact its thermal performance and ease of integration into a circuit, making it essential to consider these factors during the design process.

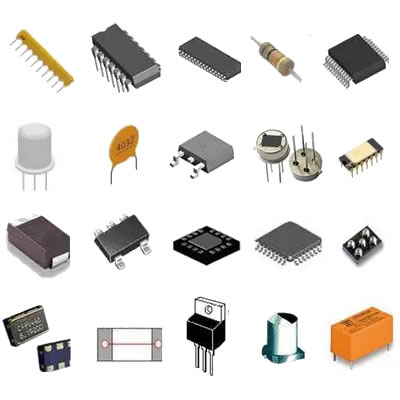

IV. Types of Non-Inductive Resistors

1. Characteristics and Applications

Wirewound non-inductive resistors are constructed by winding a resistive wire around a non-inductive core. They are known for their high power ratings and stability, making them suitable for power applications.

2. Advantages and Disadvantages

While wirewound resistors offer excellent performance, they can be larger and more expensive than other types. Additionally, they may have a higher temperature coefficient compared to other non-inductive options.

1. Characteristics and Applications

Thick film resistors are made by applying a thick layer of resistive material onto a substrate. They are commonly used in surface-mount applications due to their compact size.

2. Advantages and Disadvantages

Thick film resistors are cost-effective and suitable for mass production. However, they may have higher noise levels and lower power ratings compared to wirewound resistors.

1. Characteristics and Applications

Thin film resistors are constructed using a thin layer of resistive material, offering high precision and stability. They are often used in applications requiring tight tolerances.

2. Advantages and Disadvantages

Thin film resistors provide excellent performance and low noise, but they can be more expensive and less robust than thick film or wirewound options.

V. Performance Characteristics

1. Importance in High-Frequency Applications

The frequency response of a non-inductive resistor is critical in high-frequency applications, where inductive effects can distort signals. A flat frequency response ensures consistent performance across a range of frequencies.

2. Typical Performance Metrics

Manufacturers often provide frequency response curves for their resistors, allowing designers to assess performance in specific applications.

1. Definition of Noise in Resistors

Noise in resistors refers to the random fluctuations in voltage that can affect circuit performance. It is particularly important in sensitive applications, such as audio and measurement systems.

2. Impact on Circuit Performance

Low-noise non-inductive resistors are essential for maintaining signal integrity, especially in high-precision applications where even minor noise can lead to significant errors.

1. Factors Affecting Stability

Stability in non-inductive resistors can be influenced by factors such as temperature, humidity, and mechanical stress. Selecting resistors with high stability ratings is crucial for reliable performance.

2. Testing and Qualification Standards

Manufacturers often adhere to industry standards for testing and qualifying non-inductive resistors, ensuring that they meet performance and reliability criteria.

VI. Selecting the Right Non-Inductive Resistor

1. Identifying Specific Needs

When selecting a non-inductive resistor, it is essential to identify the specific requirements of the application, including resistance value, power rating, and tolerance.

2. Matching Resistor Parameters to Application

Understanding how different parameters affect performance will help designers choose the most suitable resistor for their needs.

1. Reputation and Quality Assurance

Choosing a reputable manufacturer with a track record of quality assurance is vital for ensuring reliable performance and longevity of non-inductive resistors.

2. Availability of Technical Support

Access to technical support can be invaluable when troubleshooting or optimizing circuit designs, making it an important consideration during the selection process.

1. Budget Constraints

While cost is always a consideration, it is essential to balance budget constraints with the need for reliable performance, especially in critical applications.

2. Long-term Value Considerations

Investing in high-quality non-inductive resistors can lead to long-term savings by reducing the risk of failure and improving overall circuit performance.

VII. Conclusion

A. Recap of Key Points

Non-inductive resistors are vital components in modern electronics, offering stable resistance without the adverse effects of inductance. Understanding their key parameters, types, and performance characteristics is essential for selecting the right resistor for specific applications.

B. Future Trends in Non-Inductive Resistor Technology

As technology advances, we can expect to see improvements in non-inductive resistor designs, including enhanced materials and manufacturing techniques that further reduce noise and improve performance.

C. Final Thoughts on the Importance of Understanding Resistor Parameters

A thorough understanding of non-inductive resistor parameters is crucial for engineers and designers. By making informed choices, they can ensure optimal circuit performance and reliability in their electronic applications.

VIII. References

A. Suggested Reading and Resources

1. "Resistor Basics" - Electronics Tutorials

2. "Understanding Resistor Specifications" - Digi-Key Electronics

B. Industry Standards and Guidelines

1. IEC 60115 - Resistors for use in electronic equipment

2. EIA-198 - Standard for Resistor Specifications

This comprehensive overview of mainstream non-inductive resistor product series parameters provides valuable insights for anyone involved in electronic design and application. Understanding these components is essential for achieving optimal performance in a wide range of electronic systems.