最新款精密电阻器 采购价格是多少?

System

Sep 19

0

最新精密电阻的购买价格是多少?

I. 引言

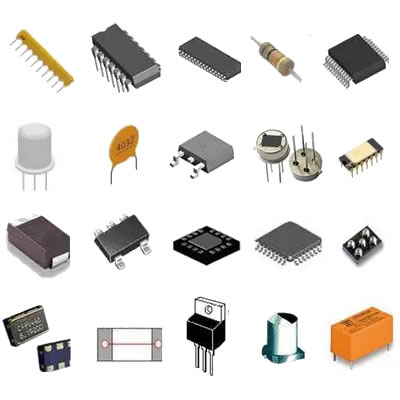

在电子世界中,精密电阻在确保电路的准确性和可靠性方面扮演着关键角色。这些组件被设计为具有特定的电阻值,且偏差最小,使得它们在高精度应用中至关重要。本文旨在探讨最新精密电阻的购买价格,揭示影响其成本的因素,并提供当前市场趋势的见解。

II. 了解精密电阻

A. 精密电阻是什么?

精密电阻是保持规定电阻值在严格公差范围内的组件。它们的特点是电阻温度系数(TCR)低,这意味着它们的电阻随温度波动变化非常小。这种稳定性对于需要准确性的应用至关重要。

1. 定义和特点

精密电阻通常由它们的公差水平定义,这些公差可以达到0.01%甚至更好。它们还因其随时间和温度变化的稳定性而区别于其他电阻。

2. 精密电阻的类型

精密电阻有多种类型,每种都有独特的特点:

薄膜电阻:以其高准确性和稳定性而闻名,薄膜电阻是通过在基材上沉积一层电阻性材料制成的。它们常用于需要高精度的应用。

厚膜电阻:这些电阻是通过在基材上印刷一层电阻性膏体制成的。尽管它们通常不如薄膜电阻精确,但由于成本效益高,被广泛应用于各种场合。

绕线电阻:通过在核心上绕制金属线制成,绕线电阻具有高精度和功率处理能力。它们常用于需要高功率耗散的应用。

B. 精密电阻的应用

精密电阻在各个领域都有应用,包括:

1. 在测量和校准中的应用

在测量设备中,精密电阻用于确保准确读数。它们常用于校准标准中,其精确的电阻值对于保持测量准确性至关重要。

2. 在高精度电路中的作用

高精度电路,如医疗设备、航空航天应用和科学仪器中的电路,依赖于精密电阻才能正确工作。任何电阻的偏差都可能导致性能出现重大错误。

Related articles

-

application development in RF Diodes for CFR-50JB-52-1R5: key technologies and success storiesSystem May 18 387Application Development in RF Diodes for CFR-50JB-52-1R5: Key Technologies and Success StoriesThe development of RF diodes, particularly the CFR-50JB-52-1R5, is a dynamic field that integrates cutting-edge technologies to enhance performance in radio frequency applications. Below, we explore key technologies and notable success stories that illustrate the impact of RF diodes across various industries. Key Technologies1. High-Frequency Diode Design2. Advanced Materials3. Integrated Circuit Technology4. Simulation and Modeling Tools5. Packaging and Thermal Management1. Telecommunications2. Consumer Electronics3. Automotive Applications4. Aerospace and Defense5. Medical Devices Success Stories ConclusionThe development of RF diodes, including the CFR-50JB-52-1R5, is propelled by advancements in materials, design methodologies, and integration technologies. The success stories across diverse industries underscore the significance of these components in enhancing performance, efficiency, and reliability in RF applications. As technology continues to advance, the role of RF diodes is expected to expand, paving the way for new applications and innovations that will further transform the landscape of radio frequency technology.Read more

application development in RF Diodes for CFR-50JB-52-1R5: key technologies and success storiesSystem May 18 387Application Development in RF Diodes for CFR-50JB-52-1R5: Key Technologies and Success StoriesThe development of RF diodes, particularly the CFR-50JB-52-1R5, is a dynamic field that integrates cutting-edge technologies to enhance performance in radio frequency applications. Below, we explore key technologies and notable success stories that illustrate the impact of RF diodes across various industries. Key Technologies1. High-Frequency Diode Design2. Advanced Materials3. Integrated Circuit Technology4. Simulation and Modeling Tools5. Packaging and Thermal Management1. Telecommunications2. Consumer Electronics3. Automotive Applications4. Aerospace and Defense5. Medical Devices Success Stories ConclusionThe development of RF diodes, including the CFR-50JB-52-1R5, is propelled by advancements in materials, design methodologies, and integration technologies. The success stories across diverse industries underscore the significance of these components in enhancing performance, efficiency, and reliability in RF applications. As technology continues to advance, the role of RF diodes is expected to expand, paving the way for new applications and innovations that will further transform the landscape of radio frequency technology.Read more -

application development in Variable Capacitance (Varicaps, Varactors) for LT1213CS8: key technologies and success storiesSystem May 17 380Application Development in Variable Capacitance (Varicaps, Varactors) for LT1213CS8: Key Technologies and Success StoriesVariable capacitance diodes, commonly referred to as varicaps or varactors, are essential components in modern electronics, particularly in applications requiring tunable frequency and signal processing. The LT1213CS8, an operational amplifier from Linear Technology (now part of Analog Devices), complements these diodes by providing amplification and signal conditioning capabilities. Below is a detailed overview of key technologies and notable success stories in the application development of varactors and the LT1213CS8. Key Technologies1. Tuning Circuits2. Phase-Locked Loops (PLLs)3. Filters4. Signal Processing5. Integrated Circuits1. Mobile Communication2. Consumer Electronics3. Automotive Applications4. Medical Devices5. Aerospace and Defense Success Stories ConclusionThe synergy between varactors and operational amplifiers like the LT1213CS8 has driven significant advancements across multiple sectors, including telecommunications, consumer electronics, automotive systems, medical devices, and aerospace applications. The ability to dynamically adjust capacitance and amplify signals has led to the development of more efficient, compact, and high-performance systems. As technology continues to evolve, the integration of varactors in new applications is expected to expand, fostering further innovation in electronic design and enhancing the capabilities of modern devices.Read more

application development in Variable Capacitance (Varicaps, Varactors) for LT1213CS8: key technologies and success storiesSystem May 17 380Application Development in Variable Capacitance (Varicaps, Varactors) for LT1213CS8: Key Technologies and Success StoriesVariable capacitance diodes, commonly referred to as varicaps or varactors, are essential components in modern electronics, particularly in applications requiring tunable frequency and signal processing. The LT1213CS8, an operational amplifier from Linear Technology (now part of Analog Devices), complements these diodes by providing amplification and signal conditioning capabilities. Below is a detailed overview of key technologies and notable success stories in the application development of varactors and the LT1213CS8. Key Technologies1. Tuning Circuits2. Phase-Locked Loops (PLLs)3. Filters4. Signal Processing5. Integrated Circuits1. Mobile Communication2. Consumer Electronics3. Automotive Applications4. Medical Devices5. Aerospace and Defense Success Stories ConclusionThe synergy between varactors and operational amplifiers like the LT1213CS8 has driven significant advancements across multiple sectors, including telecommunications, consumer electronics, automotive systems, medical devices, and aerospace applications. The ability to dynamically adjust capacitance and amplify signals has led to the development of more efficient, compact, and high-performance systems. As technology continues to evolve, the integration of varactors in new applications is expected to expand, fostering further innovation in electronic design and enhancing the capabilities of modern devices.Read more -

CFR-25JB-52-1R3 SCRs highlighting the core functional technology articles and application development cases of SCRs that are effective.System May 16 379Overview of CFR-25JB-52-1R3 SCRsThe CFR-25JB-52-1R3 is a specific model of Silicon Controlled Rectifier (SCR) that exemplifies the capabilities of SCR technology in power control applications. SCRs like the CFR-25JB-52-1R3 are designed to manage high voltages and currents, making them indispensable in various industrial and consumer applications. Below, we delve into the core functional technology articles and application development cases that highlight the effectiveness of SCRs, particularly focusing on the CFR-25JB-52-1R3. Core Functional Technology Articles1. Fundamentals of SCR Technology:2. Operating Characteristics:3. Comparison with Other Power Devices:4. Thermal Management Strategies:5. Control Techniques for SCRs:1. Industrial Motor Drives:2. Lighting Control Systems:3. Electric Heating Systems:4. Power Supply and UPS Systems:5. Renewable Energy Integration: Application Development Cases ConclusionThe CFR-25JB-52-1R3 SCR exemplifies the capabilities of Silicon Controlled Rectifiers in modern power control applications. With their ability to handle high voltages and currents, combined with effective control techniques, SCRs are integral to a wide range of industrial and consumer applications. Understanding their operational principles and application cases enables engineers and developers to leverage SCR technology effectively, driving innovation and efficiency in power management solutions.Read more

CFR-25JB-52-1R3 SCRs highlighting the core functional technology articles and application development cases of SCRs that are effective.System May 16 379Overview of CFR-25JB-52-1R3 SCRsThe CFR-25JB-52-1R3 is a specific model of Silicon Controlled Rectifier (SCR) that exemplifies the capabilities of SCR technology in power control applications. SCRs like the CFR-25JB-52-1R3 are designed to manage high voltages and currents, making them indispensable in various industrial and consumer applications. Below, we delve into the core functional technology articles and application development cases that highlight the effectiveness of SCRs, particularly focusing on the CFR-25JB-52-1R3. Core Functional Technology Articles1. Fundamentals of SCR Technology:2. Operating Characteristics:3. Comparison with Other Power Devices:4. Thermal Management Strategies:5. Control Techniques for SCRs:1. Industrial Motor Drives:2. Lighting Control Systems:3. Electric Heating Systems:4. Power Supply and UPS Systems:5. Renewable Energy Integration: Application Development Cases ConclusionThe CFR-25JB-52-1R3 SCR exemplifies the capabilities of Silicon Controlled Rectifiers in modern power control applications. With their ability to handle high voltages and currents, combined with effective control techniques, SCRs are integral to a wide range of industrial and consumer applications. Understanding their operational principles and application cases enables engineers and developers to leverage SCR technology effectively, driving innovation and efficiency in power management solutions.Read more -

application development in Single Diodes for CFR-25JB-52-1M3: key technologies and success storiesSystem May 15 386Application Development in Single Diodes: Key Technologies and Success StoriesWhile the CFR-25JB-52-1M3 is a resistor model, the world of single diodes is rich with innovation and application development. Below, we explore key technologies in single diodes and highlight notable success stories that illustrate their impact across various industries. Key Technologies in Single Diodes1. Silicon and Wide Bandgap Semiconductors2. Schottky Diodes3. Zener Diodes4. Avalanche Diodes5. Integrated Diode Solutions1. Power Supply Efficiency2. Solar Energy Optimization3. Telecommunications Advancements4. Electric Vehicle (EV) Innovations5. Consumer Electronics Enhancements Success Stories in Application Development ConclusionThe development of single diodes has been pivotal in advancing various technologies across multiple industries. Innovations in materials, design, and integration have led to more efficient, reliable, and compact electronic solutions. As the demand for high-performance electronics continues to grow, the role of diodes will expand, driving further advancements in applications ranging from renewable energy to consumer electronics. If you have specific applications or technologies in mind, feel free to ask for more detailed insights!Read more

application development in Single Diodes for CFR-25JB-52-1M3: key technologies and success storiesSystem May 15 386Application Development in Single Diodes: Key Technologies and Success StoriesWhile the CFR-25JB-52-1M3 is a resistor model, the world of single diodes is rich with innovation and application development. Below, we explore key technologies in single diodes and highlight notable success stories that illustrate their impact across various industries. Key Technologies in Single Diodes1. Silicon and Wide Bandgap Semiconductors2. Schottky Diodes3. Zener Diodes4. Avalanche Diodes5. Integrated Diode Solutions1. Power Supply Efficiency2. Solar Energy Optimization3. Telecommunications Advancements4. Electric Vehicle (EV) Innovations5. Consumer Electronics Enhancements Success Stories in Application Development ConclusionThe development of single diodes has been pivotal in advancing various technologies across multiple industries. Innovations in materials, design, and integration have led to more efficient, reliable, and compact electronic solutions. As the demand for high-performance electronics continues to grow, the role of diodes will expand, driving further advancements in applications ranging from renewable energy to consumer electronics. If you have specific applications or technologies in mind, feel free to ask for more detailed insights!Read more -

CFR-50JB-52-1M3 Single IGBTs highlighting the core functional technology articles and application development cases of Single IGBTs that are effective.System May 14 376Core Functional Technology Articles1. Understanding IGBTs: Basics and Operation2. Thermal Management in IGBT Applications3. Switching Characteristics of IGBTs4. IGBT Gate Drive Circuits1. Renewable Energy Inverters2. Electric Vehicle (EV) Powertrains3. Industrial Motor Drives4. Uninterruptible Power Supplies (UPS) Application Development Cases ConclusionThe CFR-50JB-52-1M3 single IGBT is a highly effective component across various industries, including renewable energy, electric vehicles, industrial automation, and power supplies. Its core functional technologies—such as efficient switching, robust thermal management, and optimized gate drive design—make it a preferred choice for modern power electronics applications. The application development cases underscore its practical benefits, demonstrating how the CFR-50JB-52-1M3 contributes to enhanced performance, energy efficiency, and reliability in real-world scenarios. As industries continue to evolve towards more efficient and sustainable solutions, the role of IGBTs like the CFR-50JB-52-1M3 will remain pivotal.Read more

CFR-50JB-52-1M3 Single IGBTs highlighting the core functional technology articles and application development cases of Single IGBTs that are effective.System May 14 376Core Functional Technology Articles1. Understanding IGBTs: Basics and Operation2. Thermal Management in IGBT Applications3. Switching Characteristics of IGBTs4. IGBT Gate Drive Circuits1. Renewable Energy Inverters2. Electric Vehicle (EV) Powertrains3. Industrial Motor Drives4. Uninterruptible Power Supplies (UPS) Application Development Cases ConclusionThe CFR-50JB-52-1M3 single IGBT is a highly effective component across various industries, including renewable energy, electric vehicles, industrial automation, and power supplies. Its core functional technologies—such as efficient switching, robust thermal management, and optimized gate drive design—make it a preferred choice for modern power electronics applications. The application development cases underscore its practical benefits, demonstrating how the CFR-50JB-52-1M3 contributes to enhanced performance, energy efficiency, and reliability in real-world scenarios. As industries continue to evolve towards more efficient and sustainable solutions, the role of IGBTs like the CFR-50JB-52-1M3 will remain pivotal.Read more